Date

November 18, 2014

Category

LED, Street LightingWe will be installing new lighting poles, LED fixtures, a lighting control cabinet, and conduit for a newly constructed roundabout at the intersection of MD20 (High Street) and MD 291 (Morgnec Road) in Chestertown, Maryland, for the Maryland State Highway Administration. LMI’s innovative approach to lighting and ability to think outside the box was put to the test almost immediately. The foundations for the 40’ light poles had to be drilled and installed to a depth of 13’. However, at 6’, we encountered the water table, causing both sand and water to pour into the hole faster than we could remove it.

We went back to the drawing board to find a solution. After several days of collaboration between LMI’s Director of Pre-Construction, and Linthicum’s head mechanic and master fabricator we designed and fabricated three special saw-tooth auto locking caissons, each 30” in diameter and 11’ long. The raw materials for this project were acquired as far away as New Jersey.

The caissons were drilled into the ground which supported the loose sand allowing us to reach the required 11’ depth. To drill the caissons into the ground required LMI’s 52,000 lb specially outfitted National Crane with Digger Derrick motor that both spun the Caissons and applied enormous down pressure.

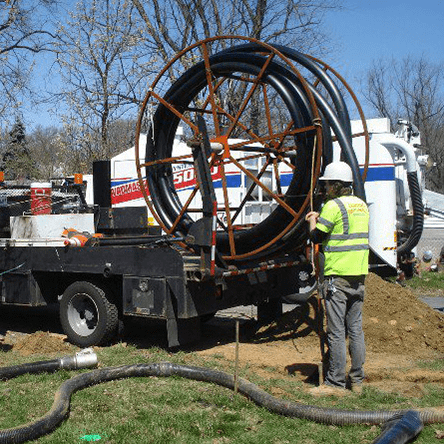

Upon reaching the proper depth, we used our VacMaster 5500 Air Excavation System to remove the sand, and a high pressure pump to remove water from the hole. Once complete, the crew had to begin the concrete pour immediately, filling the caisson above the water table. The LMI crew then pulled the caisson completely out of the ground and continued to finish the concrete pour. LMI’s crews repeated this process for each of the pole foundations.